Products Description

Model No.: Float Shoe

Brand: YAOU

Applicable Industry: Energy &Amp; Mining

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Uae, Uzbekistan, Kazakhstan, Pakistan, Russia, Sri Lanka

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Uae

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc

Status: New

Place Of Origin: China

Warranty Period: 1 Year

Warranty: 1 Year

Condition: New

Video Outgoing-inspection: Provided

Machinery Test Report: Provided

Material: Stainless Steel

Marketing Type: New Product 2020

Place Of Origin: Jiangsu, China

Applicable Industries: Energy & Mining

Certification: Api

Machine Type: Drilling Tool

Use: Well Drilling

Processing Type: Forging

Brand Name: Yaou

Showroom Location: Egypt, Uae, Uzbekistan

Local Service Location: Egypt, Canada, Turkey, France, Germany, Viet Nam, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Kenya, Chile, Uae, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan

Type: Float Collar And Float Shoe

Packaging: fumigation-free wooden case for 5-1/2 Non Rotating Downhole cementing tools casing float collar and float shoe

Productivity: 1000

Transportation: Ocean,Land,Air,Express

Place of Origin: CHINA

Supply Ability: 100

Certificate: API

HS Code: 8431431000

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal,Western Union

Incoterm: FOB

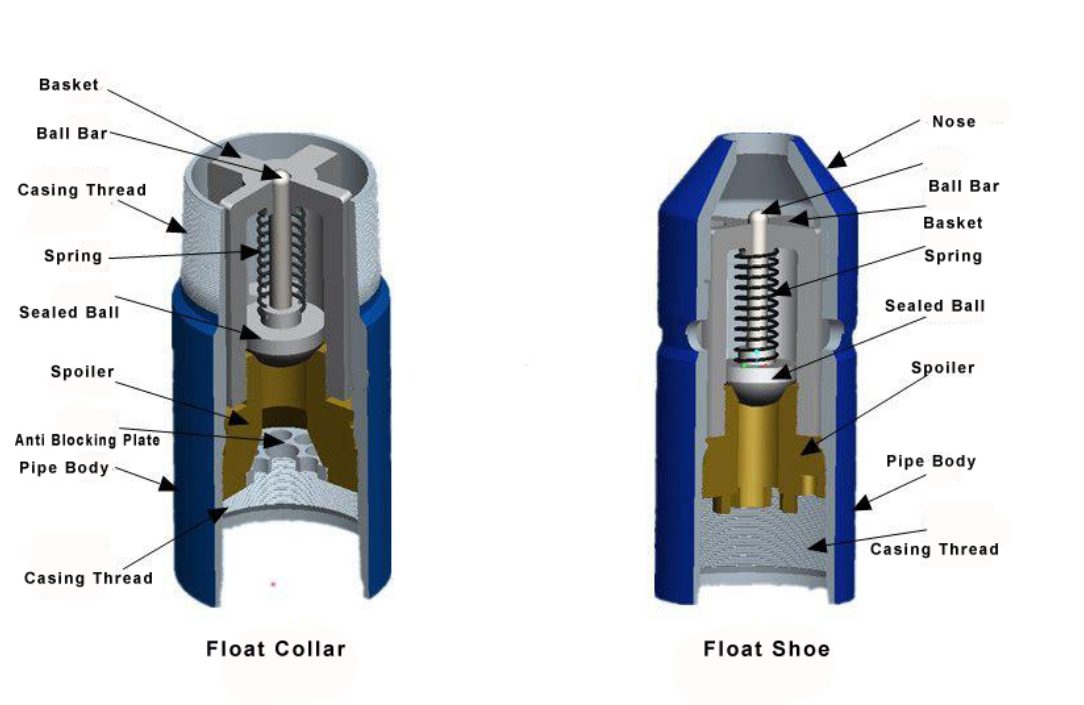

Float shoe contains a backpressure valve that prevents fluids from entering the casing while the pipe is lowered into the hole and prevents cement from flowing back into the casing after placement, while enabling circulation down through the casing. Float shoe and float collar applications:

Float collar is installed on the casing and up the float shoe. Like float shoe, it also provide buoyancy to the casing string when it’s lowered, reducing the load on the drilling rig. A build-in Check Valve provides buoyancy to the casing string also prevents cement from re-entering the casing after it’s displaced. It’s receptacle to cement plug.

Float shoe and float collar features:

1. All inner parts are made of easily drillable aluminum alloy.

2. The device can be connected directly to the casing of the same type.

3. Reliable back-pressure leak proof structure, enable grout or slurry flow with less resistance.

4. Valve seat and valve disk can effectively prevent grout from flowing back.

5. Non-rotating landing plate is available on request.

6. Either PDC or rock bit drillable.

|

Specification(in)

|

O.D.(mm)

|

Total length(mm)

|

I.D. (mm)

|

Min.Dia. (mm)

|

Conn Type

|

Affordable strength of b

ack-pressure(Mpa) |

|

|

Float Collar

|

5

|

141.30

|

500

|

110

|

50

|

5 BCSG

|

35

|

|

5 1/2

|

153.67

|

530

|

112

|

55

|

5 1/2BCSG

|

35

|

|

|

7

|

194.46

|

586

|

162.5

|

77

|

7 BCSG

|

35

|

|

|

9 5/8

|

270

|

720

|

225

|

77

|

9 5/8 BCSG

|

35

|

|

|

13 3/8

|

365

|

720

|

319

|

77

|

133/8 BCSG

|

35

|

|

|

20

|

533.4

|

720

|

475

|

77

|

20 BCSG

|

35

|

|

|

Float Shoe

|

5

|

140.30

|

495

|

110

|

50

|

5 BCSG

|

35

|

|

5 1/2

|

153.67

|

514

|

122

|

55

|

5 1/2 BCSG

|

35

|

|

|

7

|

194.46

|

533

|

162.5

|

77

|

7 BCSG

|

35

|

|

|

9 5/8

|

269.88

|

550

|

225

|

77

|

9 5/8 BCSG

|

35

|

|

|

13 3/8

|

339.7

|

550

|

319

|

77

|

133/8 BCSG

|

35

|

|

|

20

|

534

|

652

|

475

|

77

|

20 BCSG

|

35

|

|

Transportation is based on customers in different regions using steam, rail, road and air transportation.

Rugao You Inport & Export Co. LTD was established in 2004, which was among the earliest trading companies strongly supported by Ministry of Foreign Trade and Economic Cooperation.Through the past ten years, our company has already established a deep strategic cooperation relation with domestic suppliers who specilizes in oil drilling equipments, and become the top level supplier of some well known large or medium sized SOEs such as CNPC and Sinopec. The products made by our company are exported to Europe, America, the Middle East, North Africa and Southeast Asia and other regions, because of which, we enjoy widespread praise among customers at home and abroad. Our mainly products: drilling rig parts, drilling equipment, solid control system, wellhead equipment, fishing tools, cementing tools. All the productions is within the standard of API and authorized by ISO9001:2000.

Our company mainly deals in Hardware Tools, combined tools, electric tools, Special Tools For Petroleum, Metal Processing Machinery and petroleum drilling equipment. Diagonal Cutting Plier,Oil Drill Pipes,Drilling Tools,Diesel Engine Etc.Our companyoperates hardware tools and has established long-term and stable cooperative relations with many retailers.

Main products:

1. Drill Pipe, Heavy Drill Pipe, Square & Hexagonal Kelly

2. Drill Collar & Non-magnetic Drill Collar

3. Stabilizers, Reamer, Hole Opener, Casing Scraper, etc

4. Kelly Valve, Safety valve, Check valve, and float valve

5. Hydraulic or Mechanical Drilling Jar, and Absorber

6. Fishing tools (Bowen serials), including overshot, spear, etc

7. Junk Mill, Casing Cutter, Safety Joint, etc

8. Hydraulic Bucking unit, Screw up and breakout Unit, Down hole motor tester, Jar tester, etc.

9 .Down hole motor

10. Processing Machinery: shears, bending machines, hydraulic presses, bending machines, etc.

11. Various coal mine winches, oil field winches, ship winches, etc.

12. Various hand tools and electric tools.

A1: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output,

Q2. What if I use this machine for the first time and know nothing of it ?

A2: We will have our engineers teach you how to operate it,you can just inform us some details of the product you need then we can customize as your special order.

Q3. How does your factory do regarding quality control?

A3: We has been regard quality as the priority. We always attach great importance to quality controlling from the very beginning to the very end ,so our press can match all the CE and ISO standard also more strict standard .

Q4. How about your delivery time?

A4: Generally, it will take 35 working days after receiving your deposit payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have standard machines in stock.

Q5. What is the warrantee period of the machine?

A5: We can supply 1 year warranty for our machines, We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. after-sales service

A6: 1. Installation:Free installation and commissioning, travel expense is on foreign customer.(Including round ticket and

accommodation cost)

2. Personnel training: Our engineers will give your employees free machine training when they come to your company to assemble the machines, and welcome to our factory to learn how to operate our machineQ1. How to get an accurate quotation?.

Tags:

Technical parameter

Rotating Downhole cementing tools casing 1

Rotating Downhole cementing tools casing 2

Rotating Downhole cementing tools casing 3

Rotating Downhole cementing tools casing 4

Rotating Downhole cementing tools casing 5